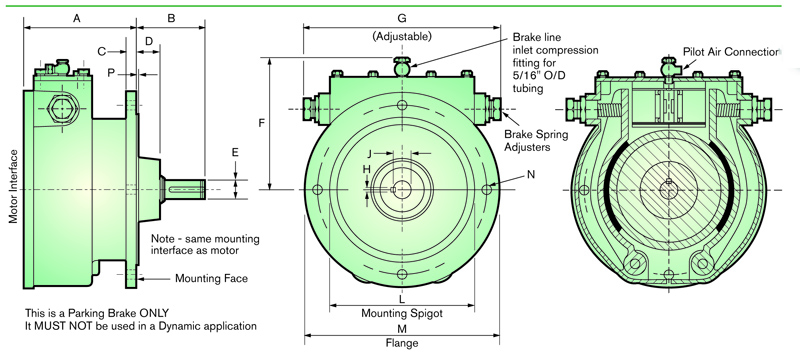

The brake module bolts directly onto the motor mounting face and has exactly the same interface as the motor. As shown on the drawing below, the brake

consists of two spring applied shoes pressed against a central hub. These shoes are released by applying air pressure to the cylinder/piston assembly.

The brake torque can be varied by means of two spring adjusters。but it is normally set so that a pilot pressure of 4.1 bar /60 psi will fully release it.

Pressures below this level will progressively reduce the braking torque available. The brakes are set at the plant but it may be necessary to

make adjustments on site to suit the individual application.